Education & Resources

It is our goal to provide you with the tools and resources to understand the application and the benefits of building with LODESTAR Structures, and to provide you with additional information we feel would be beneficial to assist you in your design and construction planning.

A Better Way to Build.

Designed To Last.

Benefits of Modular

Benefits of Modular

MODULAR CONSTRUCTION

Modular construction is a product built off-site, in a controlled factory environment, by highly skilled individuals, applying calibrated equipment, using specific material, and designed to the meet or exceed building codes and standards, saving up to 50% of production time. Buildings are produced in “modules”, that when put together on site, reflect the identical design intent and specifications of the most sophisticated site-built facility – without compromise.

MODULAR CONSTRUCTION CAN BE COMPLETED FASTER

LODESTAR Modular Units are manufactured in climate-controlled facilities and delivered to the construction site for immediate installation or can be staged on location awaiting installation. This process allows manufacturing to occur throughout the year and allows builders to schedule delivery and installation in the most efficient manner specific to each project. In most cases the complete structure is erected in one to three days.

MODULAR CONTROLS CONSTRUCTION TIME and COSTS

The complexity of scheduling and managing multiple trades, equipment and supplies has the potential to result in unexpected costs, delays, and waste. LODESTAR Modular Units allow builders to easily manage the process and provides the ability to advance the building process to framed and enclosed in a very condensed period, reducing exposure to weather related delays, and with reduced demand for labor or supplies. The efficiencies prevent unexpected costs from occurring, keeping the project on budget.

MODULAR; CONSTRUCTED IN CONTROLLED ENVIRONMENTS

LODESTAR Modular Units are manufactured in climate-controlled facilities and can be stored at a location awaiting installation. Production performed by dedicated highly skilled workers, under a controlled and monitored quality process, with assurance inspections at every step of production cycle. The completed units are put though a final multi-point inspection before being released from the production plant.

MODULAR BUILDING IS GREEN

LODESTAR Modules provide a flat roof element which allows builders to repurpose disrupted ground-level greenspace to the rooftop, eliminating the negative construction impact. LODESTAR Modular Units are manufactured in regionally located climate-controlled factories where waste is reduced from the process by skilled employees, material tolerances are optimized using the proper tools in a controlled environment, and delivery distances are minimalized.

MODULAR PROVIDES OPTIMAL QUALITY

The controlled manufacturing process provides assurance all products are manufactured under optimum temperature conditions, by highly trained and skilled workers, with automated mixture controls, and allowed to cure for a consistent period. Each step of the process is essential to ensure the finished product meets the highest quality control standards in the industry.

MODULAR REDUCES CONSTRUCTION NOISE and TIME AT THE BUILDING SITE

A benefit of incorporating LODESTAR Modular Units into the construction process is that it reduces the amount and length of construction noise produced by traditional onsite construction, and once the structure is enclosed the noise is further reduced. Reducing the length and volume of noise pollution is essential when building in densely populated areas and in noise sensitive areas.

MODULAR REDUCES DEMAND FOR SKILLED LABOUR ON SITE

LODESTAR Modular Units are built offsite, reducing the demand on scheduling skilled labor at the jobsite. Reduced labor translates into reduced risk of injury, labor accidents, and reduced demand for supervisory duties. The reduced need for trades simplifies the responsibilities of the General contractor while reducing costs and construction delays.

The construction process advances quickly from footings to framed in structure, reducing the frequency of onsite inspections for construction, and building code compliance officials.

MODULAR IS BUILT PRECISE and UNIFORM EVERY TIME

LODESTAR Modular Units are manufactured to align precisely to other Modular Units. The production process is completed by highly skilled workers, under a controlled and monitored quality process, with assurance inspections at every step of production cycle.

Precast molds are engineered to specific standards, in a process that ensures all Modules are produced to the same specifications. The benefit to the builder is that any two Modules can be connected vertically or horizontally, without the need to coordinate specific modules.

MODULAR REDUCES BUILDING MATERIALS

Traditional building methods produce waste, in materials and in time spent to prepare the materials for assembly. LODESTAR Modules are manufactured under carefully managed processes, using the exact volume of required components, removing wasted materials from the process. When LODESTAR Modules are delivered to the construction site, they are installed with a reduced amount of labor, and without excess material, further reducing waste. Reducing building material waste and assembly time, further eliminates associated expense.

MODULAR REQUIRES LESS SPACE AT THE JOB SITE FOR MATERIAL STORAGE. ON-DEMAND DELIVERY ALLOWS THE OPTION TO IMMEDIATELY SET INTO PLACE

A common challenge on construction sites is secure storage and placement of supplies and related equipment, with consideration to the exposure to theft or being damaged. Builders can store LODESTAR Modules offsite until they are ready to be installed, with the option to have delivery and installation coordinated to occur in sync with each task. The process of building with LODESTAR Modules reduces the demand for skilled labour which in turn reduces the need for space for workers to occupy, space for construction equipment, and space for employee parking.

MODULAR BUILDING UNIT’s ARE MADE OF FIRE-RESISTANT MATERIAL

Unlike wood or steel, concrete does not burn, soften, or bend. Concrete structures are more likely to remain standing through a fire. As the infrastructure of the building, fire-resistance enhances safety and security during the construction process and of the finished product. The structure’s fire rating satisfies a higher level of fire code requirements, allowing for a more versatile use of the structure in more industry sectors.

MODULAR CONSTRUCTION MEANS LESS DISRUPTION

A benefit of incorporating LODESTAR Modules into the construction process is that it reduces the amount and length of construction noise produced by traditional onsite construction, and once the structure is enclosed the noise is further reduced. Reducing the length and volume of noise pollution is essential when building in densely populated areas and in noise sensitive areas. Infill construction can be completed with a minimal disruption to surrounding residents, and with minimal disruption to local traffic, saving both time and money required to obtain permits and dealing with complaints.

REDUCED CONSTRUCTION SCHEDULE

Because off-site manufacturing of LODESTAR Modules occurs simultaneously with the site and foundation work, projects can be completed up to 50% sooner than traditional construction methods.

ELIMINATE EXPOSURE TO WEATHER DELAYS

LODESTAR Module manufacturing is completed in a factory environment, which mitigates the risk of weather delays. Modules are delivered on time, and can be installed immediately, creating a faster return on construction investment.

SAFER CONSTRUCTION

The indoor manufacturing environment reduces the risks of accidents and related liabilities for workers. The on-site modular assembly process further reduces risks associated with traditional framing and roofing techniques by instantly achieving a series of construction stages, by positioning the Module into position.

LIMITLESS DESIGN OPPORTUNITIES

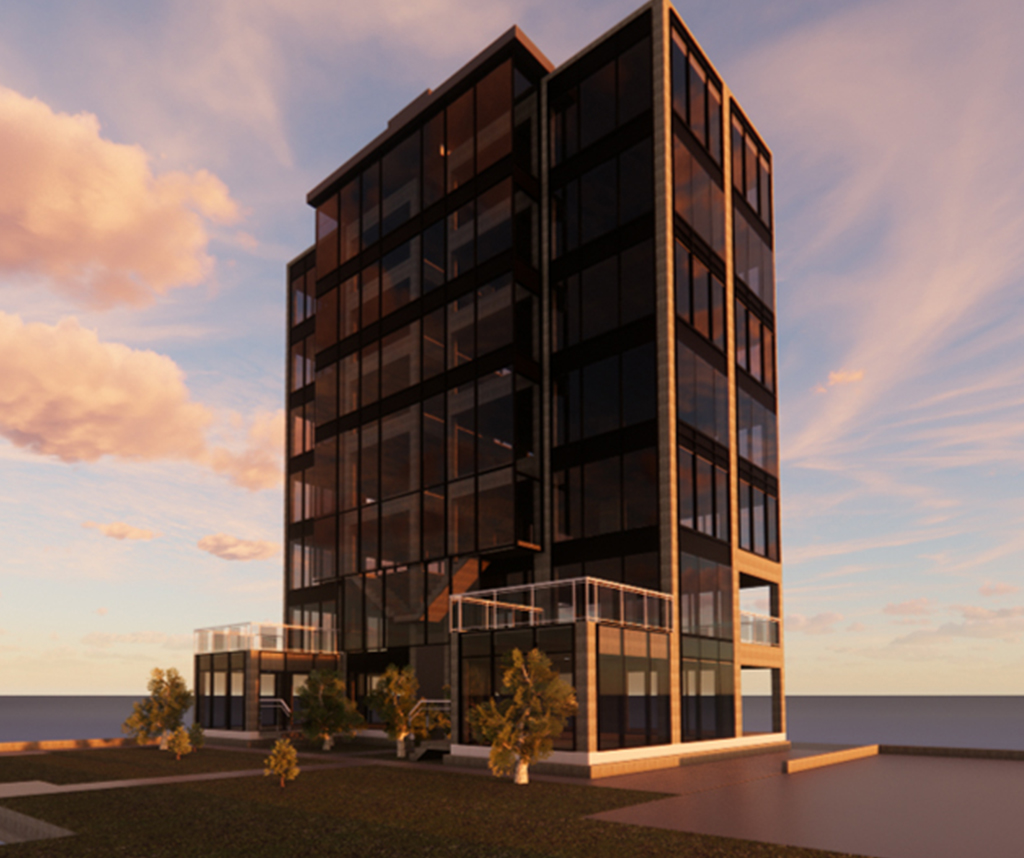

LODESTAR Modules can be stacked and connected to create a limitless selection of design options, while providing unique rooftop patios and greenspaces. LODESTAR Module characteristics can be incorporated into unique designs or the Modules can be completely concealed in the design. The finished building could provide unique and custom aesthetics or could simulate structures indistinguishable from traditionally counterparts.

Benefits of Concrete

Benefits of Concrete

WHAT IS CONCRETE?

Concrete is the most-produced man-made material on Earth. Concrete’s durability, strength and cost effectiveness make it the optimum building material for infrastructure networks worldwide. Houses, schools, hospitals, recreational amenities, airports, bridges, highways, and rail systems have been made possible with the use of Concrete. The use of concrete in the construction process is steadily increasing to keep up with the demand for urban development, construction to withstand extreme weather events, and the price of other infrastructure materials continues to rise.

Concrete can be incorporated in several key aspects to make projects more durable and disaster resistant. For example, concrete support columns and floor & roof systems offer an unsurpassed combination of structural strength and wind resistance. In addition, hardened exterior finishes for walls and roofs of a home or business provide an optimal combination of strength and security.

CONCRETE IS COST EFFECTIVE

Building with concrete is cost effective due to the ability to have components produced under extreme quality-controlled processes, in climate-controlled conditions, and delivered to the construction site as a ready to be installed building component. Time and material savings, combined with the reduction in labor requirements, and less opportunities for unforeseen events, allows projects to be completed on time and withing budgetary expectations.

CONCRETE IS DURABLE

A concrete structure is a long term, quality-based building material, in many ways superior to traditional wood or steel-framed structures. A concrete infrastructure can withstand higher degrees of water and moisture, infestation, fire, and extreme acts of nature such as tornadoes, hurricanes, and earthquakes.

CONCRETE PROVIDES STRENGTH

Concrete structures are better able to resist damage from extreme weather, and generally last longer. Damage from major weather events is less severe and affected communities will spend less energy and fewer resources repairing their community, allowing them to quickly recover to pre-disaster status.

CONCRETE IS ENGERGY EFFICIENT

Concrete retains surrounding temperatures for prolonged periods, moderating temperature fluctuations and minimizing temperature transfer between the exterior and the interior of a building. The concrete mass retains heat absorbed from sunshine, which is gradually released over the nighttime, and absorbs the cool during the evening which is gradually released during the daytime hours. This results in significantly reduced heating and cooling costs, provides a more consistent and comfortable environment, and allows the temperature to be managed by smaller and more efficient HVAC systems.

CONCRETE IS LOW MAINTENANCE

Concrete is durable and resilient, capable of withstanding weather extremes and required minimal maintenance or upkeep. The inherent resistance to erosion, rot, or insects, ensures buildings will be structurally secure for up to ten times the life expectancy of traditional building materials.

CONCRETE CONSTRUCTION SAVES TIME

Building with concrete saves time, allowing builders to complete large sections in a shorter period, using forms, pouring onsite, or precast solutions. Each application provides its own series of benefits and flexibility of use.

CONCRETE CAN BE USED IN CONSTRUCTION IN A WIDE VARIETY OF WEATHER EXTREMES

Concrete sets at a regular ambient or room temperature and can be used with minimal temperature management. Concrete can also be produced specifically to set in a variety of weather or climate variations. Modular building units can be manufactured in climate-controlled facilities where temperatures are regulated, and product schedules can be managed without climate related concern.

CONCRETE PROVIDES DESIGN AESTHETICS

LODESTAR precast concrete Modules make up the main infrastructure, around which the building is constructed, allowing architects and builders to utilize a wide variety of traditional and modern building materials to enclose and finish the construction. LODESTAR Modules are built to the highest quality standard including a smooth finished surface which, if desired can be left exposed as design characteristics otherwise not available with traditional building materials. LODESTAR Modules provide the best of both options, while adding multiple levels of design and structural integrity and durability.

CONCRETE IS VERSATILE

Concrete is a common product used in most construction projects, can be matched with material used on external features of Pools, driveway, retaining walls, etc. Concrete can be stamped, molded, colored, finished, or enclosed with other material, to achieve desired design aesthetics. The structural integrity allows concrete to be used as both a structural material and a finishing material, suitable for use in most construction projects.

CONCRETE CAN BE RECYCLED

Concrete can be produced in the exact amount required for a specific job, eliminating the opportunity for excess product which is often attributed to waste. Concrete can also be 100% recycled and used repeatedly in construction projects.

CONCRETE ENCOURAGES ADAPTIVE RE-USE

Concrete is produced to both last for an extended period, and with the flexibility to be converted multiple times, used for other purposes throughout its lifecycle. When casted into Modular components it adds to the ability of re-use and repurposing the products by relocating or adjusting the purpose of the existing structure.

CONCRETE MAKES BUILDINGS QUIETER

Concrete dampens noise and reduces noise transfer than traditional materials, reducing noise from transferring from internal and external sources. The reduction of sound transfer results in quieter spaces and increased privacy.

CONCRETE CAN BE SOURCED LOCALLY

Concrete can be produced locally, delivered to the construction site with reduced delivery and travel times. Delivery schedules can be coordinated to ensure the necessary volumes are delivered when and where required, further reducing delays and associated costs. Producing concrete locally ensures the material is produced to withstand the local climate conditions.

CONCRETE REPRESENTS RESOURCE EFFICIENCY

A prominent raw material in concrete is limestone, which is one of the most abundant resources on the planet. Concrete can also be produced with alternative materials including waste biproducts from steel mills and power plants.

CONCRETE CAN WITHSTAND HIGH TEMPERATURES

Unlike wood or steel, concrete does not burn, soften, or bend, concrete structures are more likely to remain standing through a fire. As the infrastructure of the building, fire-resistance enhances safety and security during the construction process and the finished product. The structure’s fire rating satisfies a higher level of fire code requirements, allowing for a more versatile use of the structure in more industry sectors.

CONCRETE IS PERFECT FOR CONSTRUCTION IN REGIONS WITH HIGH HUMIDITY

Moisture does not affect concrete to the degree it would wood or metal materials. Buildings built near waterfront or in areas at risk of flooding will have a much longer lifespan if they are constructed out of Concrete vs. wood or steel. Most buildings incorporate concrete into the design, often used for flooring, footings, or subterrain walls. Concrete is used due to its strength, durability, and resistance to environmental elements.

Benefits of Lodestar

Benefits of Lodestar

Benefits of building with LODESTAR Modules

LODESTAR Modules provide designers and architects an extended platform to create unique and custom design options. Modules can be used as the infrastructure around which they can design traditional designs, or specific characteristics can remain exposed to achieve custom and unique features. LODESTAR Module features can remain exposed to provide a transition from internal building features to external features of pools, driveways, retaining walls, etc.

Take full advantage of the benefits of natural light in your home

Make the design of your home suit your LOT, and take optimal advantage of sunlight, with consideration to sunrise and sunset. In many modern subdivisions one is offered a set of house plans with pre-determined door and window locations. These plans may suit the home if it is located facing the same direction it was designed for, however when a buyer choses a lot in a traditional sub-division their driveway and garage will be located to suit the lot and the road, leaving less than positive effects on windows and door locations in relation to the sun. Lodestar modules provide equal structural spans on all walls, which would accommodate windows and doors equally on all sides of the building.

LODESTAR building units provide a 2 hour fire rating, made of fire resistant material

Unlike wood or steel, concrete does not burn, soften, or bend. Concrete structures are more likely to remain standing through a fire. As the infrastructure of the building, fire-resistance enhances safety and security during the construction process and of the finished product. The structure’s fire rating satisfies a higher level of fire code requirements, allowing for a more versatile use of the structure in more industry sectors.

FASTER PROJECT COMPLETION

LODESTAR Modules are prebuilt offsite and can be scheduled for delivery to construction sites as required. For large projects Modules can be staged at the construction site and used on demand, the identical modular nature allows the Modules to be deploying without the need to use specific modules. Modules can be rapidly placed into position, reducing the framing time by as much as 90%. Each MBU provides framing and roofing features, reducing additional steps, and allowing an accelerated enclosure and finishing schedule. Building with LODESTAR Modules can reduce construction projects by up to 50%.

REDUCED LABOR REQUIREMENT

LODESTAR Modules provide the primary framework for the building, reducing the need for most of the framing and roofing crews. Fewer subcontractors are needed in this type of construction, lowering labour costs, and increasing productivity within a smaller labour force. Combining modular building material further reduces the labour requirements while further expediting the construction process.

IMPROVED UTILIZATION AND SCHEDULING

Operations, scheduling, and administration becomes more efficient using LODESTAR Modules. Building materials can be custom ordered in predetermined sizes and volumes, reducing the demand for onsite measure-and-cut tasks, allowing project managers to concentrate on completing tasks quickly and efficiently. LODESTAR Modules immediately provide protection from weather elements, providing the framework which allows construction teams to rapidly enclose the building and minimizing the risk of weather-related construction delays.

MINIMIZE WASTE

LODESTAR Modules reduce time-waste, material-waste, delay-waste, and resource-waste. Modules are prebuilt offsite in a factory where exact materials are calculated and used, they are delivered to the construction sites on schedule, and allow for an accelerated on-site construction process with reduced skilled labour and trades. The structural integrity of Modules allows architects to remove non-essential construction features such as trusses and traditional roofing. The efficiencies experienced in all aspects of the construction cycle allow the project to proceed on schedule, with reduced risk of unforeseen costs.

LOWER INSURANCE RATES

LODESTAR Modules are made of durable precast concrete, significantly reducing potential property damage and loss during disasters like storms, floods, and fire. Insurance premiums during construction may also be reduced due to reduced fire damage and material theft. Modules are positioned into place using cranes, reducing the need for workers to construct framing or roofing at dangerous heights, limiting exposure to insurance claims related to workplace accidents. Concrete is less susceptible to moisture or water damage, which could result in structural damage or material rot, which would lead to costly insurance claims and likely increased insurance premiums.

PLAN FOR FUTURE EXPANSION WITH EASE AND MINIMAL COSTS

The modular design allows for future expansion plans with ease and minimal costs. Modules can be added Horizontally and/or Vertically at the time of original construction or can be schedule for a future-dated expansion phase.

Product benefits

Never replace shingles again!

Harvest rainwater for resiliency and storm water tax credits

Get the full advantage of the benefits of the sun, sunrise, sunset, and direction of sunlight.

Lifecycle costing of the building is greatly reduced due to longevity of concrete structures

Reusability of the modules allows you to reuse the modules rather than demolishing

Modules can be added or removed from a design over time, with ease. Modules do not have to be demolished if the building design requires changing.

Modules are moisture resistant, reducing the risk of material being damaged during construction, and over the lifecycle of the structure. Moisture is a leading cause of structural damage or deterioration in traditionally built buildings.

Removing and relocating some-or-all of the modules can be done with ease, as facility use changes.

Frequently Asked Questions

LODESTAR Modular Building Units are designed to be connected Horizontally and Vertically, in a modular nature, allowing for an unlimited layout options. The first-floor units are secured to footings, while upper level units are connected to the modules beneath them leveraging the features of the supporting unit(s).

NO. The modules reduce construction framing time buy as much as 75%, and overall construction time by up to 50%. The modules are manufactured year-round in a climate-controlled facility, allowing them to be delivered to the site on specific dates and immediately placement. This systematic process allows the builder to focus on enclosing the structures and focussing more time on completing the interior of the building. Enclosing the building in a shorter period allows builders to complete projects that would otherwise be scheduled around seasonal weather and severe weather events.

The MBU’s do not require the use of specific material or building methods.

Our Modules are designed to accept prefabricated wall cladding, windows and doors, and to accept a variety of building materials or methods to enclose the structure. The MBU’s are designed with threaded wall anchor inserts on vertical surfaces, allowing you to connect modular wall cladding or have a builder enclose the units using a building method of your choice.The MBU structures have been approved for residential applications up to 7 levels (for a project in Kingston Ontario Canada). There is no limit to the number of MBU’s that can be connected horizontally. Regional building codes should be investigated and adhered to.

Certified builders have been trained and experienced with the process of installing the MBU’s, however due to the simplified installation requirements most builders and contractors would be able to follow the installation blueprints and effectively install MBU’s. If additional information or support is required, our team of experts is available to provide knowledge, support, and information to ensure the builder understands how to complete the project.

The modules are designed at a direct 2 to 1 ratio, allowing contractors and designers to use either of the two sizes to build a floorplan layout that meets the needs of the occupant. The 2 to 1 ratio allows you to use two MBU-218 to create the same layout as one MBU-436. If your location prevents you from transporting or hoisting the MBU-436, you can simply connect two MBU-218 to create the same footprint, with no space or layout compromise.

MBU’s were designed to achieve maximum transportation efficiency on a variety of roads and highways. The delivery range for Anchor has been set based on a cost efficiency calculation. The delivery area generally includes locations within 100KM from Kingston. Some locations may require special planning, please contact us directly to confirm delivery is available.

Our MBU’s are designed to be transported on most major roadways without the need for specialty permits and with traditional planning. The transportation trailer is outfitted with a custom support system that securely carries the module from the storage location to the building site. The module can be lowered from the trailer using the built in hydraulic system, can be hoisted from the trailer directly into place, or can be stored at the building site for future installation.

Our MBU’s have been carefully designed with a forward-thinking approach, allowing the builder to accommodate standard and advanced utility systems. Each unit is designed with a cavity in the ceiling area, allowing for services to be installed and concealed. The modules have aligning utility ports which allow services to be transferred between modules without the need for excessive re-working.

Yes, MBU's intentionally designed to incorporate traditional building styles and methods, in a Hybrid fashion. You can construct a wood frame section of the building on the roof of an MBU or you could build Horizontally using the MBU as a primary support frame, adding other framing methods affixed to the MBU.

Yes, all MBU’s can be connected Vertically or Horizontally to create the desired layout. There are requirements how the MBU’s are connected to ensure structural integrity and to allow access ports to line up. The dimensions of the MBU-218 is exactly half of the dimensions of the MBU438, which serves the purpose of allowing builders to connect 2 X MBU-218’s together to create the same footprint as one MBU-436. This benefit also allows for add-on structures to be connected, Vertically or Horizontally, to the primary building in later years, if the need for additional space is required.

Absolutely, the modules are the ideal sizes for building TINY HOUSES, Starter Homes, Hobby and Recreational Buildings, Outbuildings, Shelters, and so many more applications.

Absolutely, the modules are ideal for building garages, hobby and recreational buildings, outbuildings, shelters, and so many more applications.

Absolutely, the modules are the ideal sizes for building Tertiary suites, Tiny Homes, Starter Homes, Hobby and Recreational Buildings, Outbuildings, Shelters, and so many more applications.

Yes, the modules are weather resistant and can be stored in extreme weather conditions without compromising the integrity. The MBU’s are built to exact specifications and are built to connect to each other in a Modular manner, allowing builders to store the units on site and use them as required. MBU’s are built to connect to other MBU’s without having to match specific units together.

Licensed and approved Manufactures can produce LODESTAR Modules in their factories for delivery to their market region. Delivery regions will vary, search for approved manufacturers in the Partners section on our website, contact your local approved manufacture to confirm availability in your area. In many cases orders can be scheduled for future dated deliveries, ensuring builders can rely on inventory being delivered in a timely manner. A benefit of producing the MBU’s in a climate-controlled facility is the ability to produce high quality finished products every month of the year regardless of seasonal weather conditions.

The Modules are available in two sizes. Careful consideration was used in the design plans to maximize the effectiveness of the capabilities related to the size offerings, while maximizing transportation, manufacturing, and delivery efficiencies.

The two sizes allow a high volume of design flexibility, due to the standardization of the support pillars, allowing for simplified installation while maintaining maximum structural integrity. If additional height is required, the first-floor units can be installed on elevated footings, allowing commercial, retail, hospitality, residential, and other spaces to achieve the desired interior height.In most cases, yes you can add MBU’s to expand existing buildings constructed of traditional building materials. A common application incorporating LODESTAR Modules is known as a Hybrid-structure, which combines LODESTAR Modules with traditional building material to expand the variety of design features.

The requirement to add MBU’s to an existing structure is to prepare required foundation & footings for the MBU’s to be positioned. The MBU’s can be connected vertically to add multi-level additions adjacent to existing structures. Local building codes should be investigated to confirm the requirements and to acquire necessary building permits.Resources are available to help you design and plan your construction project.

Product Specifications

Integer feugiat purus et feugiat ornare. Class aptent taciti sociosqu ad litora torquent per conubia nostra, per inceptos himenaeos. Duis quis enim libero.

Product Assembly Information

Integer feugiat purus et feugiat ornare. Class aptent taciti sociosqu ad litora torquent per conubia nostra, per inceptos himenaeos. Duis quis enim libero.

Product Use Illustrations

Integer feugiat purus et feugiat ornare. Class aptent taciti sociosqu ad litora torquent per conubia nostra, per inceptos himenaeos. Duis quis enim libero.