Key Applications

Lodestar structures are applicable to the listed types of industries.

Residential Applications

Commercial Applications

Multi-Unit Housing & Mixed Use

How to Build with Lodestar

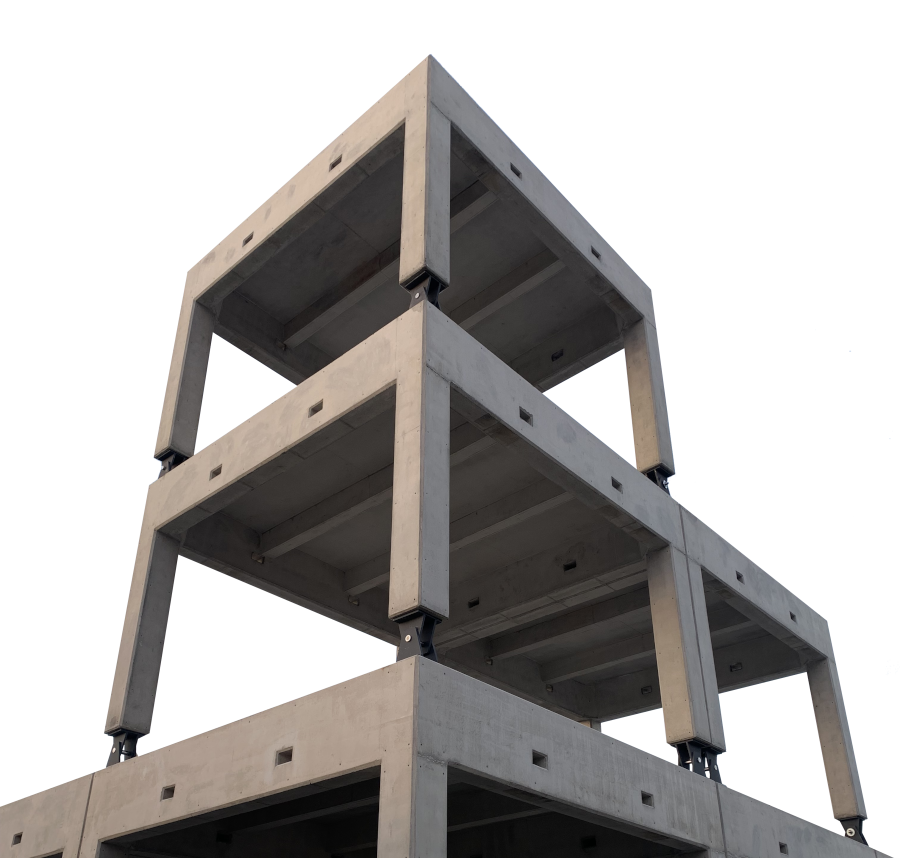

Lodestar modules are designed to be connected horizontally and vertically, in a modular nature, allowing for an unlimited number of layout options.

The first-floor units are secured to footings, while upper level units are connected to each other leveraging the features of the supporting unit(s). The modules reduce construction framing time by as much as 75%, and overall construction time by up to 50%.

The modules are manufactured year-round in a climate-controlled facility, allowing them to be delivered to the site on the day of assembly and immediately positioned into place. This systematic process allows the builder to allocate more time to enclosing the structures and advancing their teams to focus on completing the interior of the building. Enclosing the building in a shorter period allows builders to complete projects that would otherwise be scheduled around seasonal weather and severe weather events.

Imagine Your Space

See our designs

Key Advantages

Build better, build affordably, and build faster. Build without compromise.

Fast Build Time

Modules can be delivered and installed immediately, saving approximately 75% of traditional framing time.

Affordable Cost Certainty

The modules provide the structural support, roof, and floor to upper levels, all in one module. Installation is quick, and requires less labour resources. Less risk of delay or unexpected construction costs.

Environmentally Sustainable

Concrete can be produced in the exact amount required for a specific job, eliminating waste. Concrete lasts for an extended period, and with the flexibility to be converted multiple times, it can be used for other purposes throughout its lifespan.

Superior Quality

Lodestar modular building units are manufactured in a climate-controlled facility by highly skilled workers, under a controlled and monitored quality process, with assurance inspections at every step of the production cycle.

Versatile

Modules can be used in any climate. They can withstand extreme weather conditions, can be connected to create unlimited design options, and can be used in applications for commercial, residential, hospitality, and many more uses.

Reliable Build Partners

Our network of highly trained and experienced contractors and builders understand the benefits of building quality structures, with less resources, and in a shorter time.

What Our Customers Say About Us

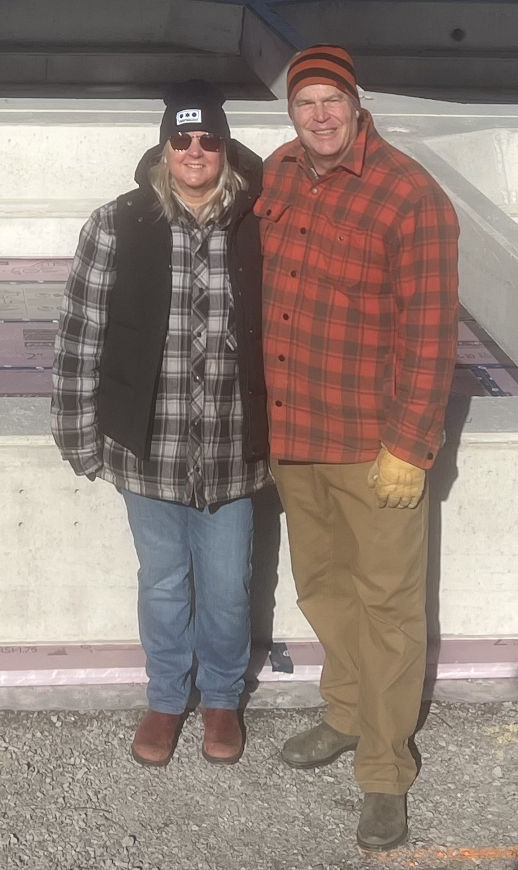

We are currently building a four season cottage in the Kingston area and we were interested in building a modular structure. In working with our General Contractor, we were introduced to Lodestar. We have been most impressed with this business and their product. From the start, they spent time with us explaining the product and process. An onsite visit to their site in Kingston allowed us to become more familiar with the concept and their product. They have assisted us with plans and design. Throughout this process, our questions have been answered quickly. At no time have we felt rushed or pressured.

In any planning, the people with who you work are so important in the process. We have been so impressed with the individuals we have met at Lodestar. We are fully confident that they will deliver an excellent, final product.

Bill and Margie Gartland

From the Blog

[blocksy_posts limit=”3″ has_pagination=”no”]

Contact Us

Contact Lodestar or a Lodestar Preferred Partner to learn more about how you can create your perfect space, with Lodestar Building Systems.

Tel: 1-833-563-3782

Email: info@LodestarStructures.com